I can modify the width, ET (offset), and diameter. Sometimes by up to an extra 3 inches.

I handle conversions, turning rims into two-piece or three-piece designs for more versatility and style. On top of that, I can personalize the color, add a chromed finish or completely overhaul the look of a rim.

One thing I’m particularly proud of is my ability to create wheels that combine both aluminium and steel. It’s a challenging process that starts with carefully extracting the steel rotor from the original rim. I then refine it meticulously to ensure a flawless surface

for bonding. The final step involves merging the steel rotor with an aluminium lip, achieving

a seamless connection between the two materials. It’s precise, detailed work, but the result is a wheel that’s as durable as it is stunning.

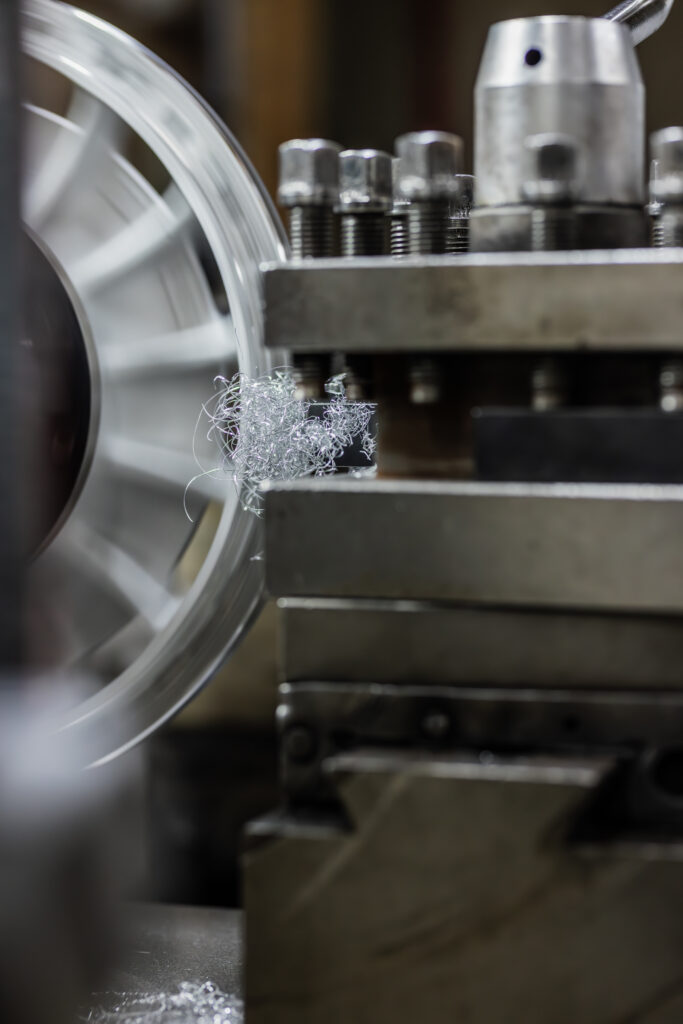

Every project I take on requires detailed planning and calculations to ensure the wheel

is perfectly matched to its car. My priority is precision, both in design and safety, so I stick

to EU-made materials, traditional tools like a conventional lathe and my custom-built machines. They might be slower than modern CNC devices, but they let me deliver

the craftsmanship I take pride in.